Value-added Cooling Systems Market: Asetek Harnesses AI and 3D Printing for Base Expansion

Individual companies operating in the cooling systems market are increasingly focusing on enhancing the technological sophistication of their products. Classic cooling systems have evolved to a certain point of efficiency. However, overcoming this barrier and advancing even further requires the utilisation of innovative technologies. Asetek, a renowned firm in the market, is reportedly planning to use artificial intelligence (AI) and 3D printing technology to refine water block base design.

As reported by the information website Overclock3D, the Denmark-based cooling systems manufacturer, Asetek, revealed this strategy at Computex 2024. The firm aims to utilise AI to enhance the design of waterblock bases, along with the latest additive manufacturing technologies. Fabric8Labs, a company providing 3D printing technologies that facilitate the creation of metal structures that otherwise cannot be achieved through traditional machining methods, has been named as a partner.

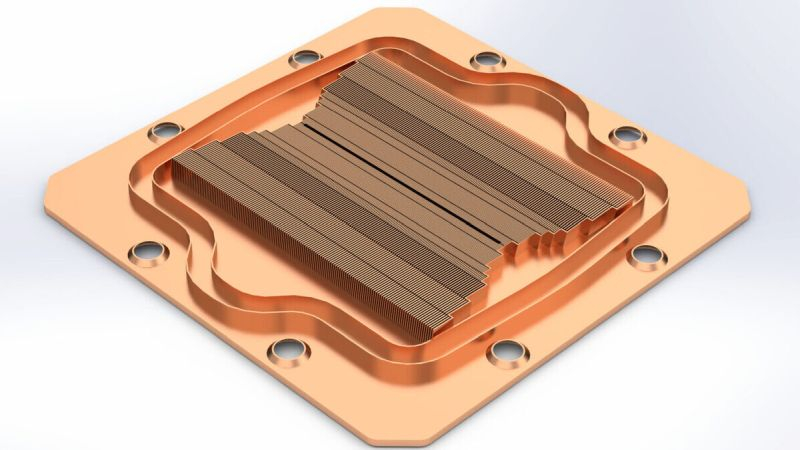

Through 3D modelling and subsequent water block base simulation, designers can select an internal element configuration that maximises heat dissipation and improves hydraulics. By reducing the structure’s resistance to liquid flow, an optimal cooling efficiency can be achieved without necessitating more powerful, and thus louder, pumps. As a result, the cooling system retains its efficiency while operating at much lower noise levels. If necessary, this technology also offers the potential to elevate performance to previously unachievable levels.

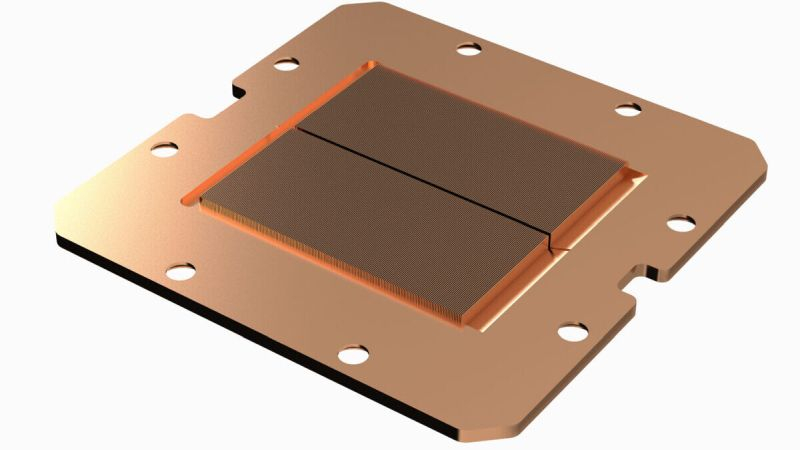

The image above depicts the 3D model of a water block base, which could be crafted through conventional metal machining methods without any additional AI-aided design optimisation. The combination of these innovative technologies paves the way for creating water block bases with more intricate shapes that functionally ensure superior cooling efficiency, as shown in the illustration below.

Such forms are not achievable through traditional metal machining, and so 3D-printing comes into play. Predictably, such innovations may influence production costs and scale, however, Asetek has not yet hinted when such products will begin being manufactured. Nonetheless, based on the foremost illustration, similar developments will likely be incorporated into cooling systems used within the upcoming Republic of Gamers (ROG) product line from Asustek Computer.