Intel Anticipates Production on 10A Process by End of 2027

Intel has revealed its intention to introduce the novel 10A process into production by late 2027, reported by attending representatives at the Intel Foundry Direct Connect event for Tom’s Hardware.

This revelation implies that Intel’s projected lithography levels would reach comparability to the 1-nm process, despite Intel’s aversion to these parallels. As per revised information, Intel plans to begin its 14A technology chip production in 2026, which would subsequently provide a one-year margin to familiarize with the 10A process. 10A’s technology would imply not only the use of EUV lithography with high-numeric aperture value but also transistor structures with surrounding gates and power supply techniques from the reverse side of the printed circuit board.

Presently, there is no clarification in terms of the progression that the 10A technology would provide, concerning transistor placement density, switching speeds and energy consumption deduction compared to predecessors. It was however stated by Intel’s CEO, Patrick Gelsinger, that the development level gap between adjacent lithography stages is occupied by 14-15% in terms of performance versus energy consumption. Regardless, a double figure percentage growth is anticipated for 10A process progression.

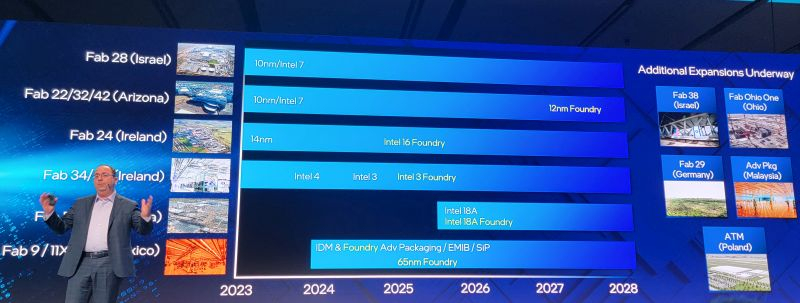

In forthcoming years, Intel’s chip production expansion will incline towards EUV lithography technologies, and the share of 10 nm and lower process norms, such as Intel 7, will decline relentlessly. Simultaneously, testing and chip packaging will expand their businesses, a service that various companies that don’t directly order Intel’s silicon wafer processing could utilize. Intel will hand over classical packaging technologies to subcontractors, keeping only the advanced packaging techniques in-house for economic advantages.

As Intel enters the contract market for chip production, a longer lifecycle for each production process and reduced production costs via an effect of scale are expected. In the next five years., Intel plans to invest $100 billion in expanding its existing production capacities and establishing new ones.

Production of 18A technology products is set to begin at Fab 52 and Fab 62 in Arizona as early as 2025. The same technology will be applied at the facilities under construction in Ohio, sparking further rumors about this project’s delay. Initially, Intel will develop 18A technology in Oregon, where its research center is located along with an experimental production line, permitting the commencement of 18A chip production by the end of the year.

The specific facility for 10A process production remains unspecified. However, an important component of Intel’s future strategic development involves incorporating artificial intelligence (AI) in its manufacturing processes. This move will see the introduction of ‘cobots’ – robots designed to work in tandem with humans on the production line. By the next decade, AI implementation scales will witness substantial growth, automating not only production processes but also enabling production plan volumes. By the end of the decade, Intel aims to rank second globally as a contract chip manufacturer.