Taiwan faced an unprecedented drought in 2021 which led to the allocation of every available freshwater reserve to support the functioning of Taiwan Semiconductor Manufacturing Company (TSMC) chip-making businesses. The island’s agriculture bore the brunt of this strategy. Analysts predict that the semiconductor industry’s pace of development could result in a water shortage for chip production, resulting in manufacturers hiking prices.

Economical Implications of Water Shortage

The reasoning of expert analysts from S&P Global Ratings is straightforward. Erecting new facilities and successfully implementing cutting-edge technology requires considerable investments. A lack of water resources for scaling production may force manufacturers to recover capital outlays by increasing product prices. This scenario could apply to TSMC, who insist on maintaining a high concentration of its advanced facilities on its homeland of Taiwan. This island faces seasonal deficits in water and electricity.

Impact of Lithographic Steps on Water Usage

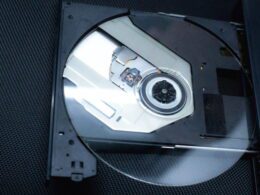

Each subsequent lithographic step in the manufacturing process increases the need for water. Water plays a pivotal role in chip manufacture, not just for cooling equipment but also for rinsing processed silicon wafers. TSMC facilities use highly purified freshwater, as lithography progresses, more intermediary rinses are required. This is due to the increasing number of technological operations. For comparison, compared to 2015 with its active usage of the 16-nm process, TSMC’s water consumption has risen by 35%. This is projected to further increase by 5-9% in the future.

Climate Change Challenge and Demand for Freshwater

Climate changes witnessed in recent years make year-round cover for all of the chip manufacturers’ needs from precipitation-derived water unrealistic. This demand is growing so significantly that the global semiconductor industry’s freshwater consumption can now be compared to that of Hong Kong, a city with a population of 7.5 million people.