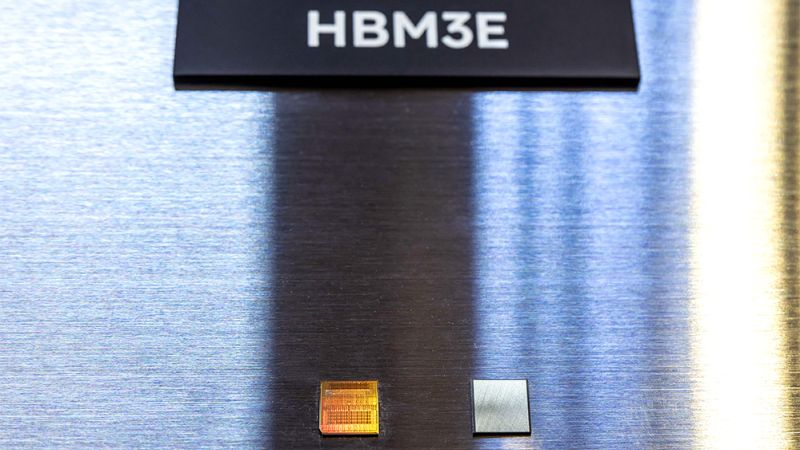

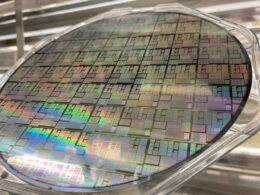

Production of HBM microchips necessitates a substantial volume of silicon wafers, not only because of the large surface area of the crystals, but also due to substantial failure rates. In the past, the production yield of HBM has never exceeded 40-60%, but SK hynix has managed to increase this figure to 80%.

This information was disclosed in an interview by Kwon Jae-soon, the Quality Management Director at SK hynix, with the Financial Times. Concurrently, the company has managed to cut the production cycle duration of HBM3E by 50%. Until now, it was assumed that the production yield of HBM3E by SK hynix did not exceed 60-70%, a number which was already considered pretty decent. The now reported figure of 80% surpasses these expectations showing SK hynix’s success in optimizing its manufacturing process.

By 2025, SK hynix foresees mastering mass production of 12-layer HBM4 memory, in collaboration with Taiwan-based TSMC. Its competitor, Samsung, aims to start production of this generation memory only in 2026. By that time, SK hynix is planning to initiate the production of 16-layer HBM4 stacks.

Mentioning Samsung’s plans to commence shipments of 12-layer HBM3E stacks in the current semester, a representative of SK hynix noted that its customers are currently demanding 8-layer HBM3E stacks the most. As such, this is currently the company’s production priority. Indeed, SK hynix plans to start supplying 12-layer HBM3E stacks in the third quarter.