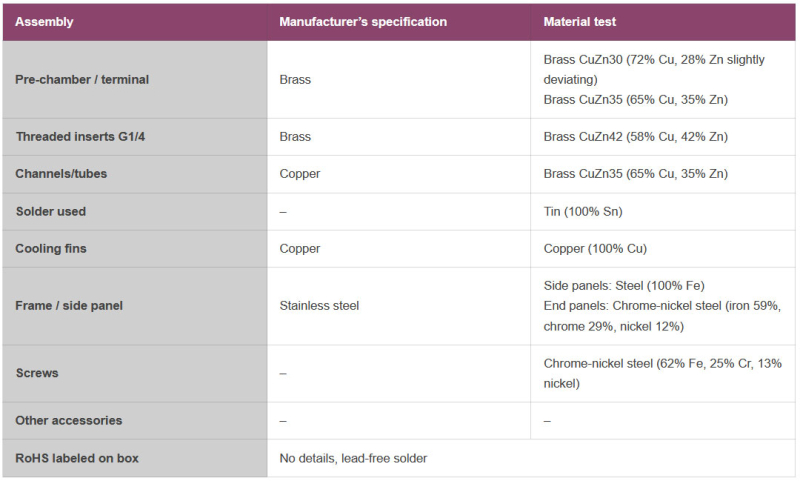

A recent investigation by Igor’s LAB revealed that half of the tested liquid cooling radiators (LCRs) did not meet their claimed specifications. The materials used differed from those stated by the manufacturer on their official websites and advertisements, often replacing expensive materials with cheaper ones, such as substituting copper with brass.

As reported by website editor Igor Wallossek, the eight-page analysis was prompted by user complaints of blockages, corroded metal parts, and overall performance issues in their liquid cooling systems. The study consisted of six radiators from different manufacturers. Replacing pricier materials with cheaper alternatives was found in three of the units.

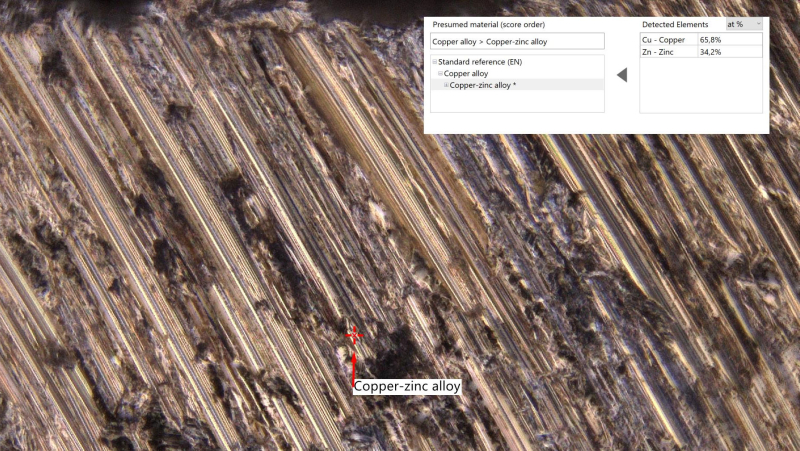

A case in point is the Watercool Heatkiller Rad 120-S Black LCR, where the advertised and actual materials used were found to differ.

The preliminary results for each of the LCRs are as followed:

Alphacool NexXxoS ST30 Full Copper X-Flow 120mm:

- A genuine copper radiator;

- All material specifications are as advertised;

- Soft material screws.

Aqua Computer Airplex Radical 2/120, aluminum radiator fins:

- Channels made of real copper;

- All material specifications are as advertised;

- A fair offering.

Bykski CR-RD120RC-TN-V2, 120mm D30 V2, all-copper radiator:

- Channels made of brass, not copper;

- Flux residue present;

- An ROHS violation – lead solder;

- Soft material screws and respective holes.

EK Water Blocks Quantum Surface P120M Black:

- Brass channels, not copper h90;

- High-quality machining;

- Flux residue;

- Soft material screws.

Hardware Labs Black Ice Nemesis GTS – 120 XFlow:

- Fully brass-made exception for cooling fins;

- Materials are functional but average in quality;

Watercool Heatkiller Rad 120-S Black:

- Brass channels, not copper;

- Quality screws and soldering.

Wallossek did not evaluate the performance of each LCR but instead focused on comparing the advertised and actual materials used. His concluding recommendation, meanwhile, was not for purchasers but manufacturers. He encouraged them to take quality control more seriously, without relying heavily on OEM manufacturers.

Although he stopped short of accusing anyone of a deliberate intent to deceive, he suggested that negligence was a significant contributing factor. Future apathy from the manufacturers may be met with more severe criticism. Wallossek plans to extend his research by anonymously purchasing more LCRs from brands like Corsair, Thermaltake, lesser-known brands, and OEM manufacturers.